Advancements in precision machining have transformed how engineers approach production timelines and part consistency. Many now turn to CNC companies near me that offer multi-spindle machines for their ability to deliver higher throughput without sacrificing accuracy. This demand reflects a shift toward smarter manufacturing, where time, efficiency, and adaptability define success on the shop floor.

More Parts Finished per Shift When Multiple Spindles Run in Sync

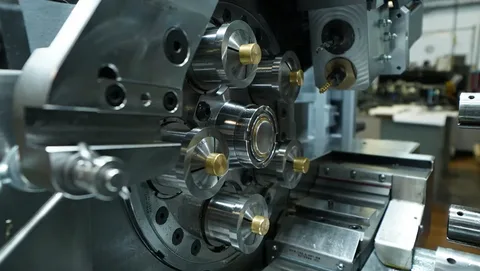

Multi-spindle machining allows several tools to cut simultaneously, dramatically increasing productivity per shift. Instead of waiting for one spindle to complete an operation before the next begins, these machines synchronize movements across multiple spindles, dividing the workload efficiently. The result is a steady flow of completed parts with shorter cycle times, especially beneficial in high-volume production runs where deadlines are tight.

In operations where consistency is key, synchronized spindles maintain precise tolerances across every component. Engineers seeking a CNC machine company that delivers repeatable quality understand that multi-spindle setups reduce variation from part to part. This technology turns once time-consuming projects into streamlined processes with faster outputs and minimal rework.

Why Tight Timelines Push Teams Toward Multi-axis Setups

Deadlines drive decisions in machining, and multi-axis equipment helps teams stay ahead. Engineers facing product launches or demanding delivery windows often choose machine shop near me options with multi-spindle and multi-axis machines. These systems complete multiple operations at once—drilling, milling, tapping, or contouring—without transferring parts between setups.

The speed comes from the ability to machine complex shapes in one continuous cycle. Fewer transitions between equipment mean fewer chances for misalignment or dimensional error. Teams looking for machining services near me value this time savings because it compresses production schedules without increasing labor costs, allowing projects to reach assembly faster.

What Materials Benefit Most from Simultaneous Cutting Tools

Certain materials respond better to multi-spindle machining due to their structure and machining properties. Metals like aluminum, brass, and mild steel benefit most because their uniform density supports simultaneous cutting without tool chatter or vibration. These materials allow each spindle to maintain steady contact with minimal resistance, ensuring consistent surface finishes across all pieces.

High-performance alloys and composites can also be machined efficiently with the right spindle configurations. Modern CNC machine shop near me operations use specialized tooling and coolant systems that stabilize temperature and prevent wear. With the ability to fine-tune spindle speeds individually, multi-spindle setups handle even tough materials with remarkable precision and speed.

Fewer Setups Needed When Machines Handle High-volume Runs

Traditional machining often requires multiple setups to complete a single part. Multi-spindle systems eliminate that by combining several operations into one cycle. For companies processing thousands of identical parts, this change means shorter downtime between jobs and fewer manual adjustments. The efficiency translates directly to more output per hour and greater overall equipment utilization.

This consolidation also minimizes handling errors and the time lost during re-clamping or fixture alignment. CNC companies near me offering such technology can produce larger orders faster, giving engineers confidence that their production schedules will stay on track. The reduction in setup frequency is one of the clearest advantages of multi-spindle machinery.

How Fast-tracked Prototyping Benefits from Split-head Machining

Prototyping once required long waits between design revisions and physical samples. Split-head machining changes that dynamic by allowing multiple prototype iterations to be produced simultaneously. Engineers can test different design tweaks without waiting for separate runs, accelerating development cycles significantly.

Machine shops using multi-spindle technology can produce these variations in parallel, maintaining accuracy while saving valuable time. For design engineers balancing innovation with production speed, this flexibility becomes an advantage that directly supports faster decision-making and quicker time-to-market results.

Can Smaller Batch Work Still Justify Multi-spindle Use

Though multi-spindle setups shine in large-scale production, smaller batches can also benefit. Precision and speed make them ideal for industries that value accuracy over quantity, such as aerospace or medical manufacturing. Each spindle can perform different operations, allowing diverse parts to be produced in a single pass rather than resetting equipment for every change.

For teams searching for machining services near me, the question isn’t just about volume but efficiency per hour. Even smaller orders see measurable savings in labor and setup time. The adaptability of these systems allows engineers to meet low-quantity, high-complexity demands without inflating project costs.

Less Downtime Means More Units Shipped in Fewer Days

Downtime is the enemy of production schedules. Multi-spindle machines reduce it by keeping operations running continuously. Each spindle can take over while another completes a cycle, ensuring no time is wasted waiting for repositioning or retooling. This overlapping workflow turns idle minutes into productive output.

For manufacturers facing tight delivery windows, that consistency directly impacts fulfillment rates. A CNC machine company equipped with multi-spindle systems can complete contracts faster while maintaining quality assurance across each batch. The outcome is faster shipping schedules and improved customer satisfaction.

How Complex Geometries Are Shaped Faster with Dual Rotation

Complex components often require intricate geometries that would typically need several passes on standard equipment. Dual-rotation spindles, operating independently or in sync, allow simultaneous machining of different faces or surfaces of a single part. This feature reduces tool changes and eliminates the need for manual repositioning.

CNC plasma cutting machine operations that pair dual-rotation spindles with automated tool changers can achieve remarkable precision in less time. The machines adapt to different contours and cuts with ease, maintaining high accuracy across complex designs. For engineers balancing performance and productivity, this technology ensures every shape and detail comes out right the first time.